Custom Machine Design and Fabrication Services Explained

- rbemltd

- Aug 19, 2025

- 4 min read

In today's fast-paced world, businesses often require specialized solutions to meet their unique needs. Custom machine design and fabrication services offer a way to create tailored equipment that fits specific operational requirements. Whether you are in manufacturing, healthcare, or any other industry, understanding these services can help you make informed decisions.

Custom machine design and fabrication is not just about creating machines. It is about solving problems and enhancing efficiency. This blog post will explore what these services entail, their benefits, and how to choose the right provider for your needs.

What is Custom Machine Design?

Custom machine design involves creating machines that are specifically tailored to meet the unique requirements of a business. This process starts with understanding the client's needs and specifications.

Designers work closely with clients to gather information about the intended use of the machine, the materials it will handle, and any specific features that are necessary.

Once the requirements are clear, designers use computer-aided design (CAD) software to create detailed plans. These plans serve as a blueprint for the fabrication process.

The goal of custom machine design is to create equipment that enhances productivity and efficiency. For example, a company that manufactures automotive parts may need a machine that can handle specific dimensions and tolerances. A custom-designed machine can ensure that these parts are produced accurately and consistently.

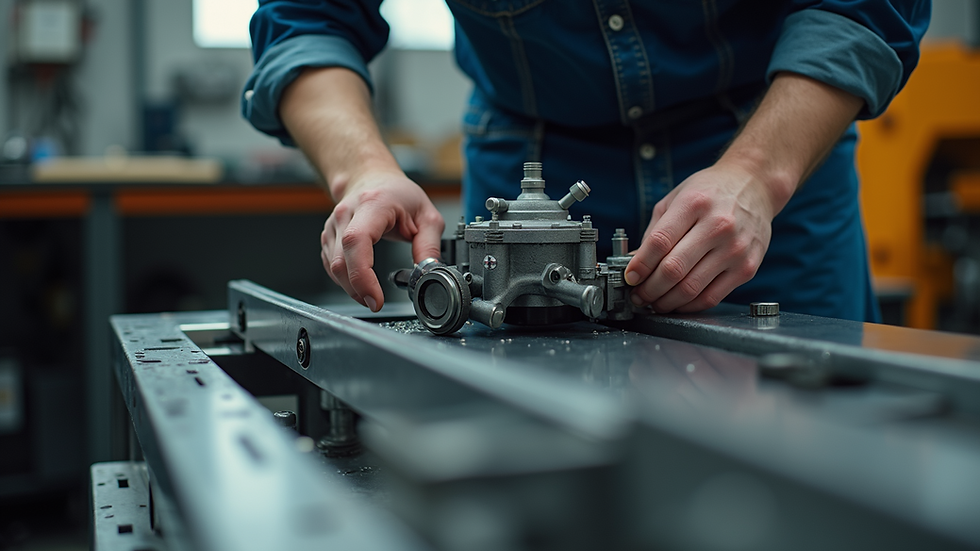

The Fabrication Process

Once the design is finalized, the next step is fabrication. This is where the actual construction of the machine takes place.

Fabrication involves several key steps:

Material Selection: Choosing the right materials is crucial. The materials must be durable and suitable for the intended application.

Machining: This process involves cutting, shaping, and assembling the materials according to the design specifications.

Assembly: After machining, the various components are assembled to create the final product.

Testing: Before delivery, the machine undergoes rigorous testing to ensure it meets all specifications and functions correctly.

Installation: Finally, the machine is installed at the client's facility, and any necessary training is provided.

Each of these steps is essential to ensure that the final product meets the client's expectations and operates efficiently.

Benefits of Custom Machine Design and Fabrication

Investing in custom machine design and fabrication services offers several advantages:

Tailored Solutions: Custom machines are designed to meet specific needs, which can lead to improved efficiency and productivity.

Increased Flexibility: Businesses can adapt their machines as their needs change, allowing for greater flexibility in operations.

Enhanced Quality: Custom machines can be designed to produce higher quality products, reducing waste and improving overall output.

Cost-Effectiveness: While the initial investment may be higher, custom machines can lead to long-term savings by improving efficiency and reducing downtime.

Competitive Advantage: Having specialized equipment can give businesses a competitive edge in their industry.

For example, a food processing company may require a custom machine to package products in a specific way. By investing in a tailored solution, they can streamline their operations and improve product quality.

Choosing the Right Provider

Selecting the right provider for custom machine design and fabrication is crucial. Here are some factors to consider:

Experience: Look for a provider with a proven track record in your industry. Experience can lead to better design and fabrication outcomes.

Capabilities: Ensure the provider has the necessary equipment and technology to meet your needs. This includes advanced machining tools and CAD software.

Communication: A good provider will communicate effectively throughout the design and fabrication process. They should be open to feedback and willing to make adjustments as needed.

Support Services: Consider whether the provider offers support services, such as installation and training. This can be invaluable in ensuring the machine operates smoothly.

Reputation: Research the provider's reputation in the industry. Look for reviews and testimonials from previous clients to gauge their reliability and quality of work.

By carefully evaluating potential providers, you can find a partner that aligns with your business goals and can deliver the custom solutions you need.

Real-World Applications

Custom machine design and fabrication services are used across various industries. Here are a few examples:

Manufacturing: In manufacturing, custom machines can automate processes such as assembly, packaging, and quality control. This can lead to significant time and cost savings.

Healthcare: In the healthcare sector, custom machines can be designed for specific medical applications, such as surgical instruments or diagnostic equipment. These machines can improve patient outcomes and streamline operations.

Aerospace: The aerospace industry often requires highly specialized equipment for manufacturing components. Custom machines can ensure precision and compliance with strict industry standards.

Food and Beverage: Custom machines can be designed for processing, packaging, and labeling food products. This can enhance efficiency and ensure compliance with safety regulations.

Each of these applications demonstrates the versatility and importance of custom machine design and fabrication services.

The Future of Custom Machine Design

As technology continues to advance, the future of custom machine design and fabrication looks promising. Innovations such as 3D printing and automation are changing the landscape of manufacturing.

3D printing allows for rapid prototyping and the creation of complex designs that were previously impossible. This technology can significantly reduce lead times and costs associated with traditional fabrication methods.

Automation is also playing a crucial role in custom machine design. By integrating smart technology, machines can become more efficient and capable of self-diagnosing issues. This can lead to reduced downtime and improved productivity.

As these technologies evolve, businesses that invest in custom machine design and fabrication will be better positioned to adapt to changing market demands.

Final Thoughts

Custom machine design and fabrication services are essential for businesses looking to enhance their operations. By investing in tailored solutions, companies can improve efficiency, quality, and flexibility.

Choosing the right provider is crucial to ensure that your specific needs are met. With the right partner, you can create machines that not only meet your current requirements but also adapt to future challenges.

In a world where efficiency and innovation are key, custom machine design and fabrication services can provide the edge your business needs to thrive.

Comments